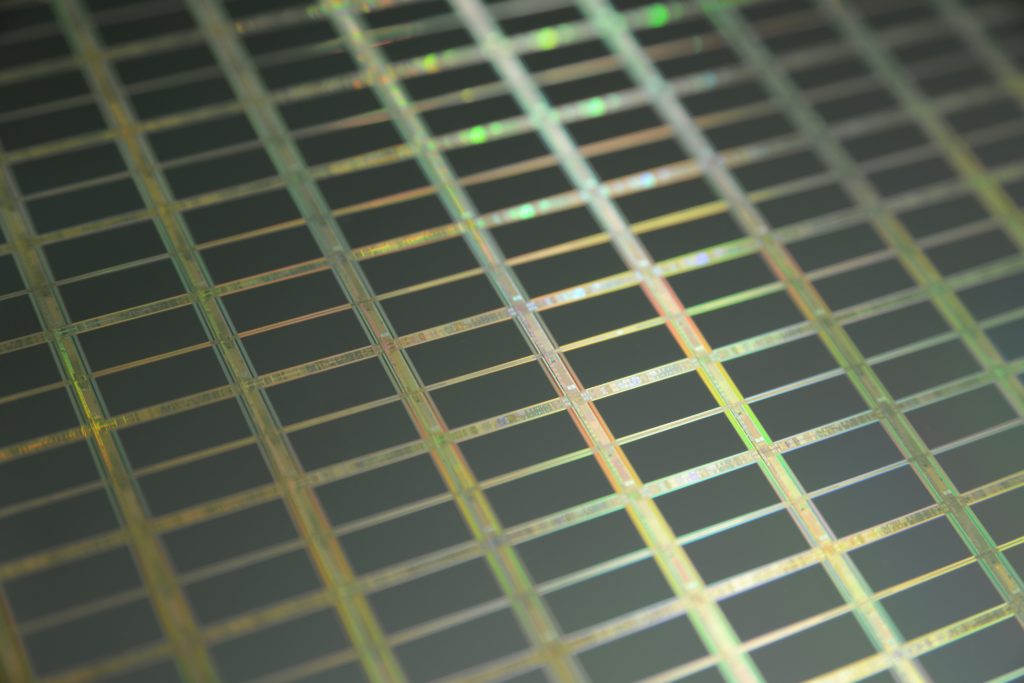

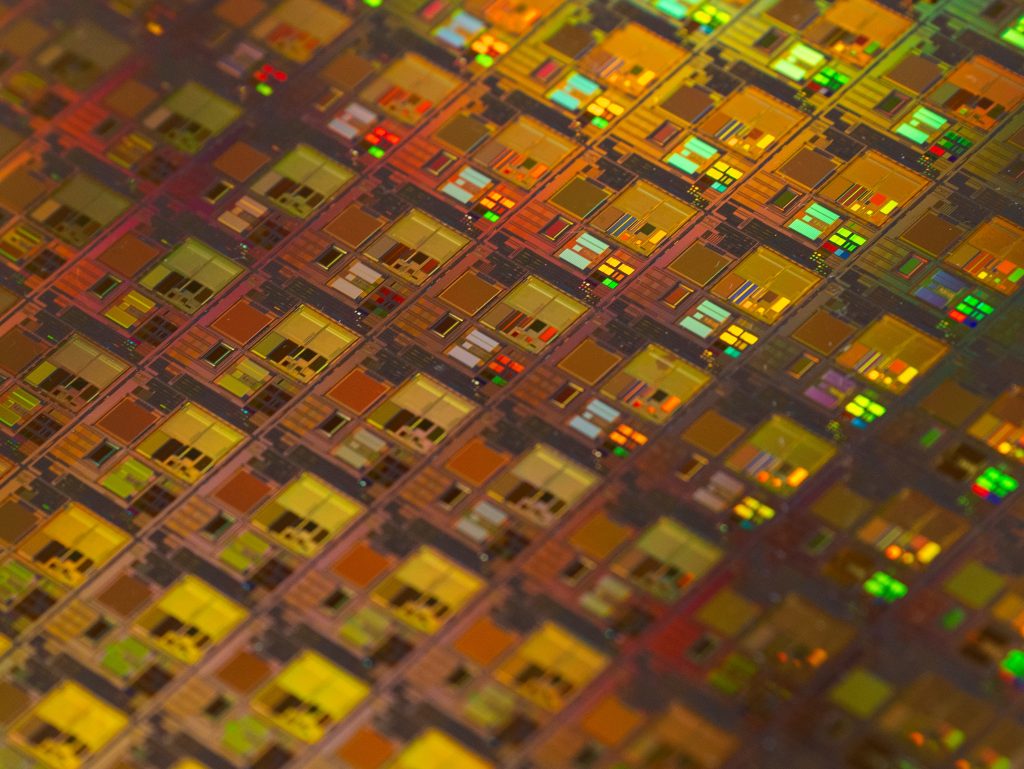

Artificial Intelligence (AI) plays an increasingly important role in semiconductor fabrication. AI is being used to automate the semiconductor process of designing and manufacturing semiconductors and optimize the process for maximum efficiency.

Additionally, AI detects and diagnoses problems in the fabrication process, allowing for faster resolution. However, deploying AI in this sector comes with a price. Irrespective, AI can help reduce overall operational costs, increase productivity, and improve product quality.

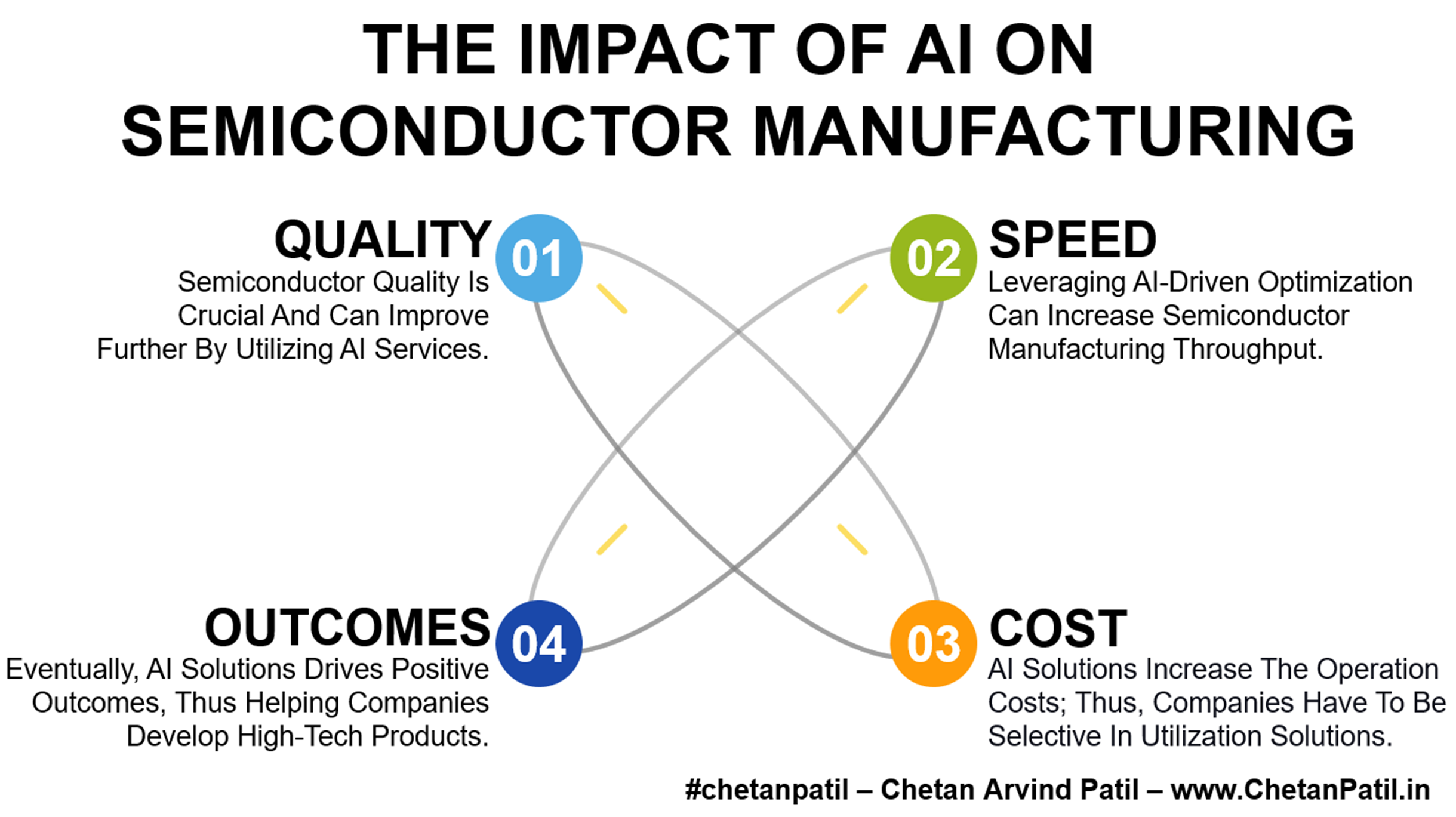

Quality: Semiconductor Quality Is Crucial And Can Improve Further By Utilizing AI Services.

Speed: Leveraging AI-Driven Optimization Can Increase Semiconductor Manufacturing Throughput.

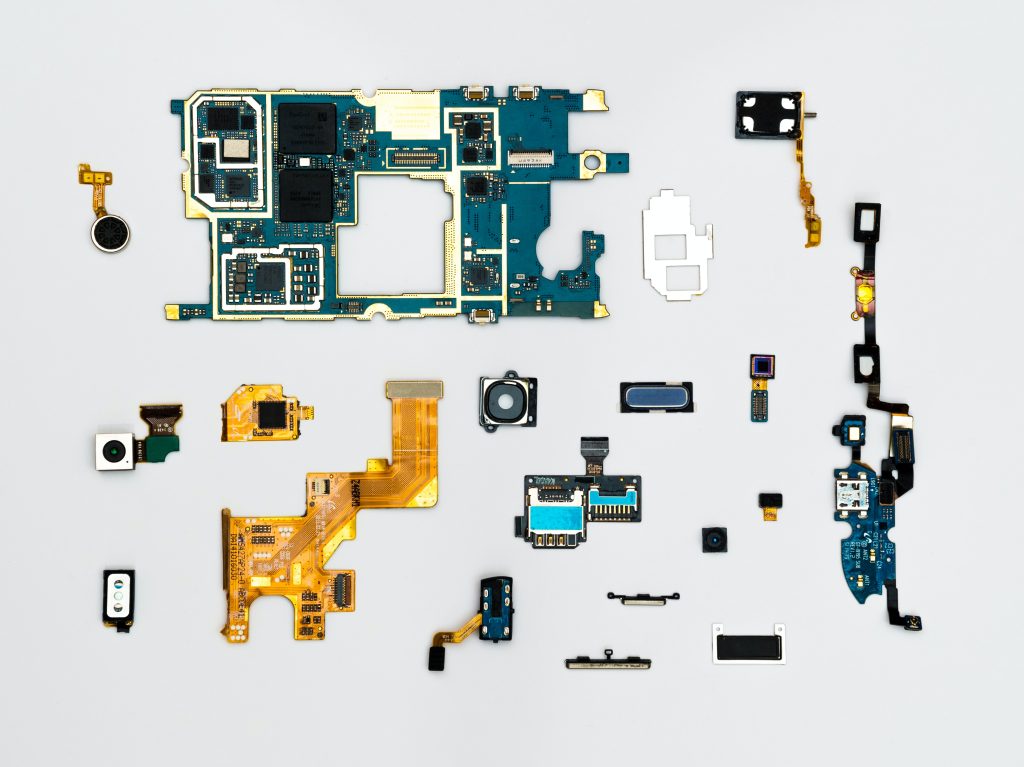

AI-driven automation can also help streamline the manufacturing process from design to delivery by analyzing the fabrication process data, identifying defects, and optimizing procedures. AI can automate several aspects of the fabrication process, allowing for faster production times and improved quality control.

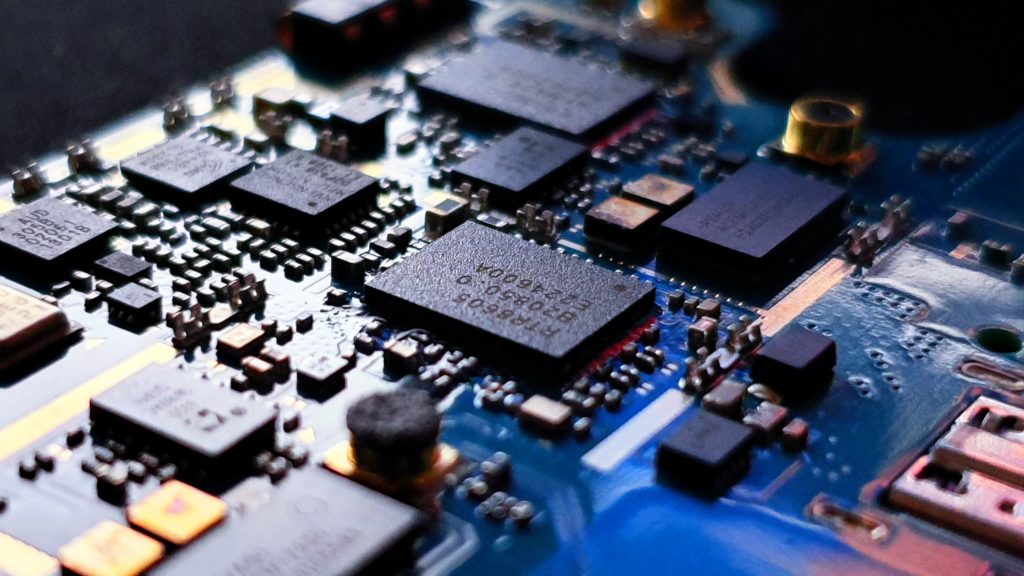

However, deploying AI in semiconductor manufacturing can take time and effort. It requires significant resources to develop AI applications’ algorithms, hardware, and software. On top, the cost of training and maintaining the AI system is also high.

Several factors drive the cost of AI in semiconductor manufacturing. Such as the complexity of the application, the size of data sets used for training, and the number of resources required to maintain it. Furthermore, additional costs are associated with integrating existing systems with new AI solutions. These factors increase the cost of deploying AI in the semiconductor industry.

Nevertheless, the future of AI in a semiconductor is encouraging. With the help of AI, semiconductor companies can develop more efficient and cost-effective solutions for their customers. Several design and manufacturing process steps currently rely on AI solutions to speed up analysis and thus help speedy production output.

Cost: AI Solutions Increase The Operation Costs; Thus, Companies Have To Be Selective In Utilization Solutions.

Outcomes: Eventually, AI Solutions Drives Positive Outcomes, Thus Helping Companies Develop High-Tech Products.

One of the better use cases of AI in semiconductor manufacturing is to predict future trends in the industry, which can help develop new products and services tailored to market needs. As a result, semiconductor companies will be able to stay competitive in the market and provide better products and services for their customers.

AI is revolutionizing the semiconductor industry by providing a range of benefits. AI-enabled semiconductors can perform complex tasks with greater accuracy and speed than ever before. With all such advantages, it is no wonder that AI is becoming an increasingly important part of the semiconductor industry.