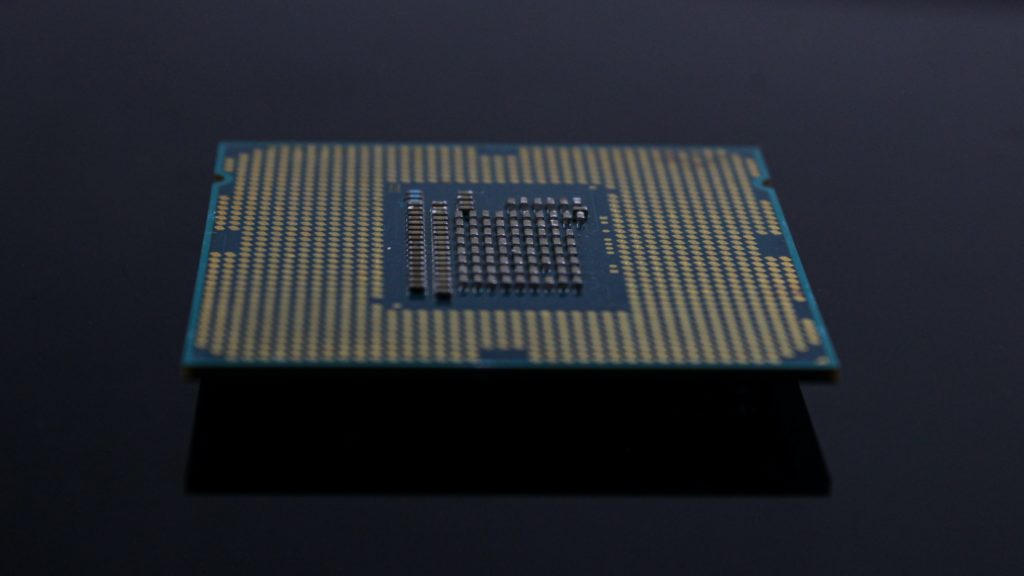

Photo by Anne Nygård on Unsplash

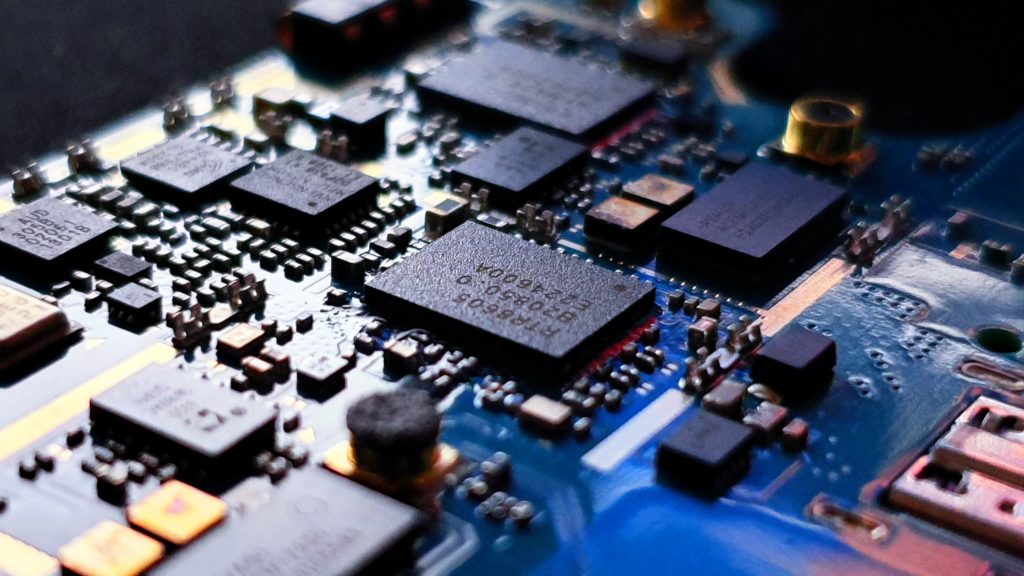

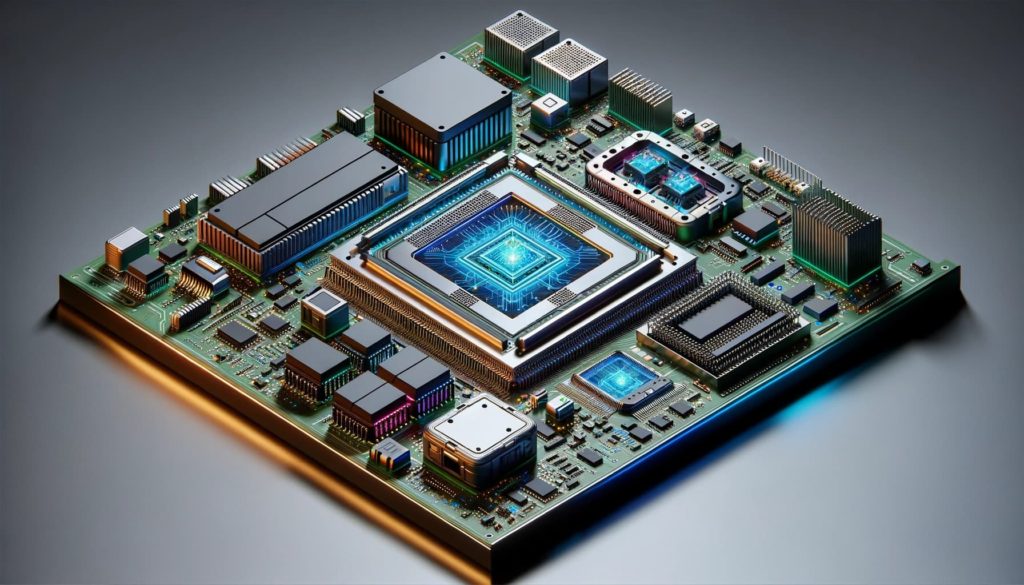

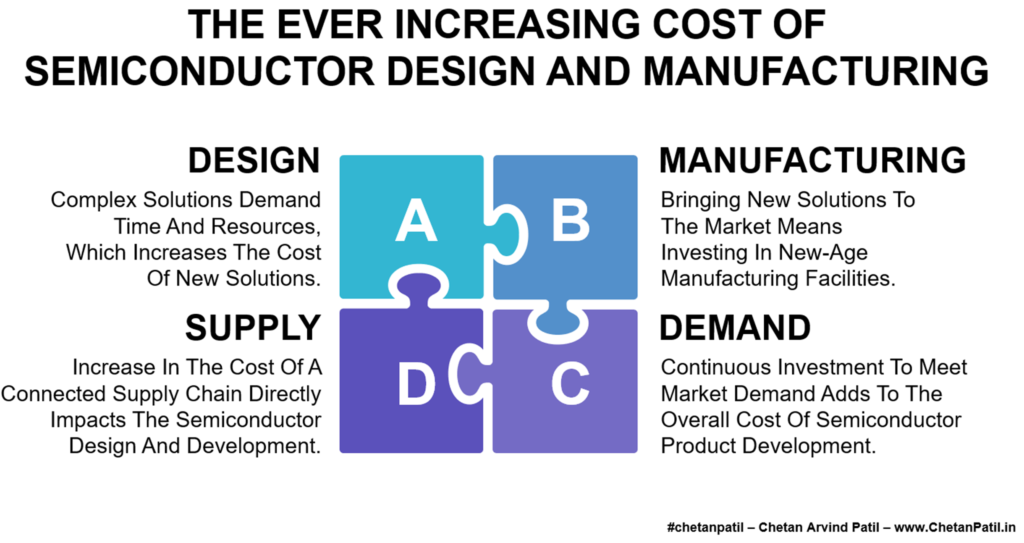

The complexity of semiconductor devices is increasing at a rapid pace. The reason is the demand for new features, which requires novel design and manufacturing approaches, which come at a higher cost due to the time, resources, and investment needed to enable new semiconductor solutions.

On the design side, it has become easier to bring up new solutions and prove them using an advanced simulation approach. Eventually, these solutions should be fabricated and validated, which costs millions of dollars, and with every next-gen design and manufacturing process, the cost of prove-in keeps increasing.

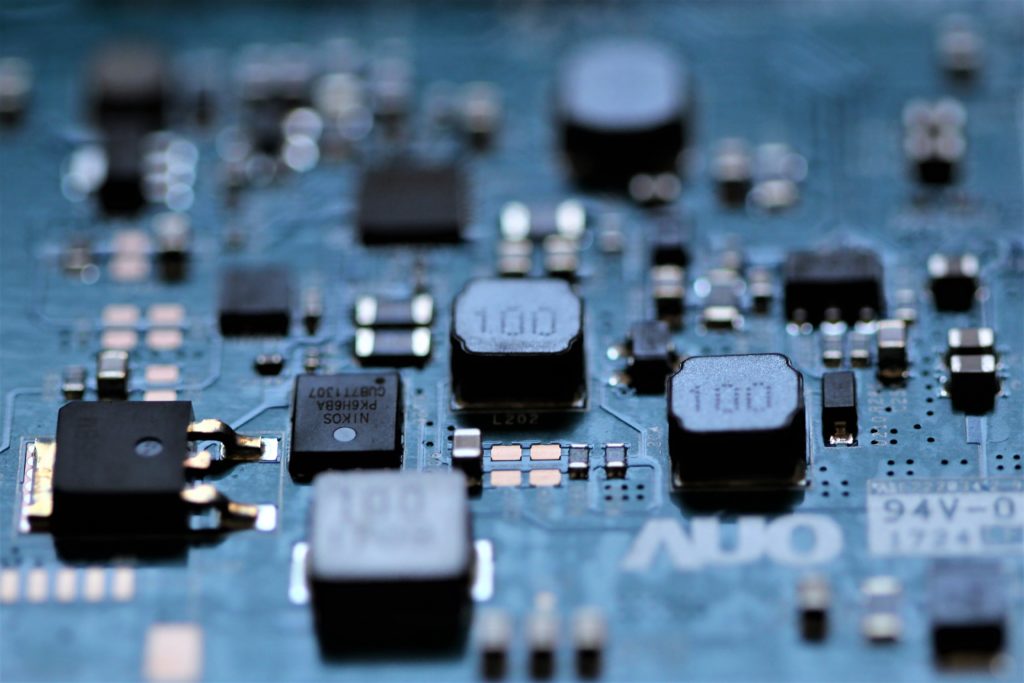

Design: Complex solutions demand time and resources, which increases the cost of new solutions.

Manufacturing: Bringing new solutions to the market means investing in new-age manufacturing facilities.

The connected (equipment, material, raw wafers, tools, and so on) semiconductor supply chain can also delay the plans, which increases the cost of introducing new solutions.

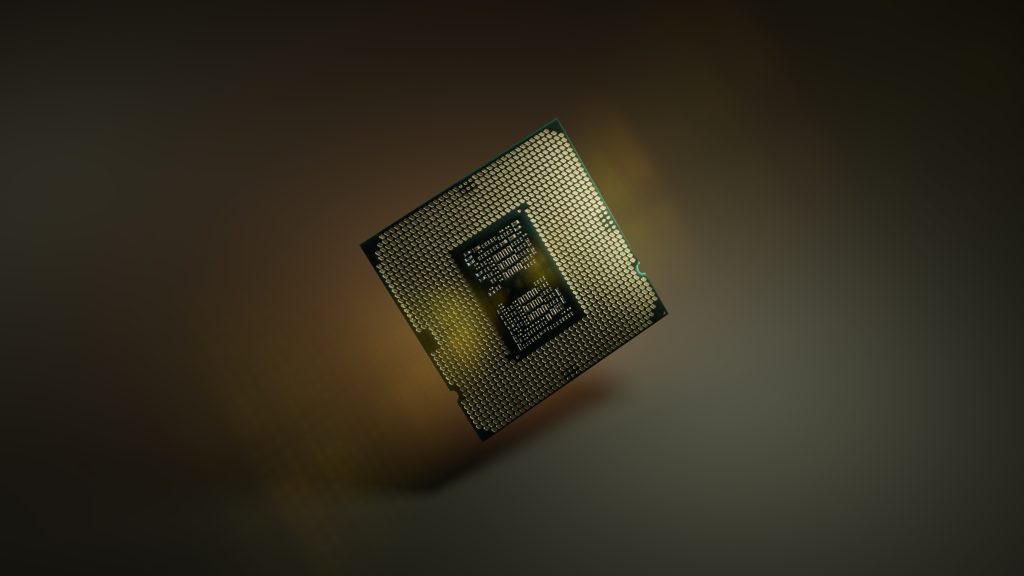

Semiconductor companies have to manage and plan future market requirements so that the new solutions are not too costly to develop. On another side, given that the semiconductor industry is highly connected and driven by the connected semiconductor supply chain, it is not easy to keep the cost of development low.

The design and manufacturing of semiconductor products are dependent on several technical factors. Apart from it, there is a business aspect (market-driven) that also impacts the total cost of semiconductor product development.

Higher demand for semiconductor products increases the need to produce more silicon chips. However, not being able to fulfill these requests on time eventually adds to the negative cost. On another side, the supply constraint of any goods needed by the semiconductor process (manufacturing equipment, wafers, materials, etc.) can increase, thus directly impacting the overall design and manufacturing cost.

Demand: Continuous investment to meet market demand adds to the overall cost of semiconductor product development.

Supply: Increase in the cost of a connected supply chain directly impacts the semiconductor design and development.

This cyclic nature of demand and supply also impacts the total cost of the semiconductor industry, more so when there is a need to add new capacity to bring supply-demand equilibrium.

As the semiconductor industry embarks on a new era of design and manufacturing processes, the need to balance the cost to enable affordable market solutions will be crucial. Otherwise, it will not be easy to drive the faster break-even point for the next-gen capacity, which will also shape the future of several semiconductor manufacturing companies.