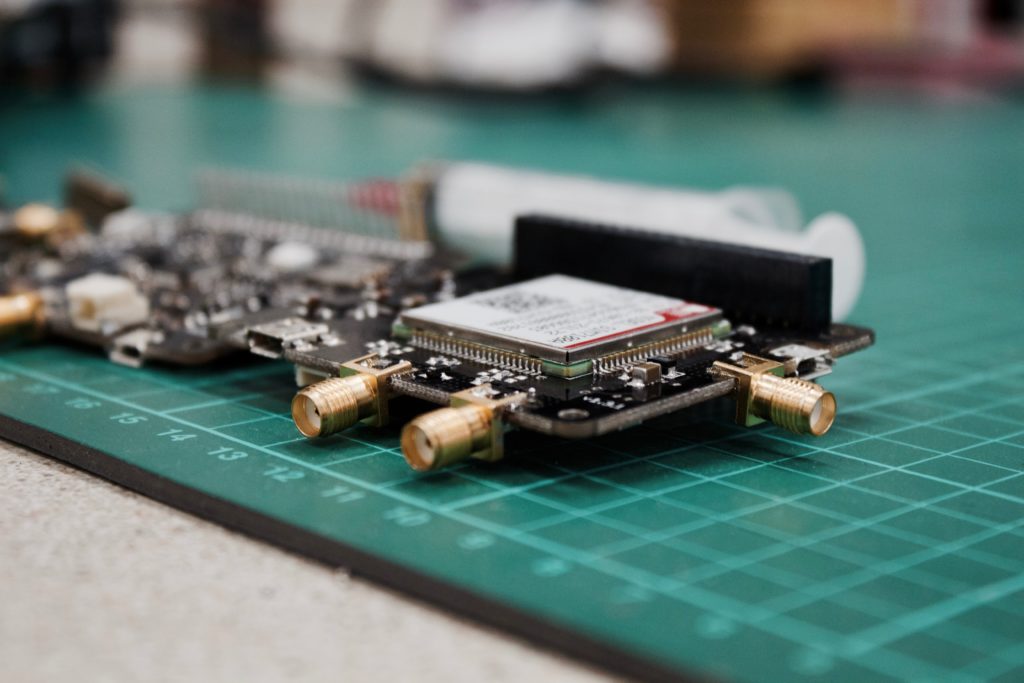

Photo by Christophe Hautier on Unsplash

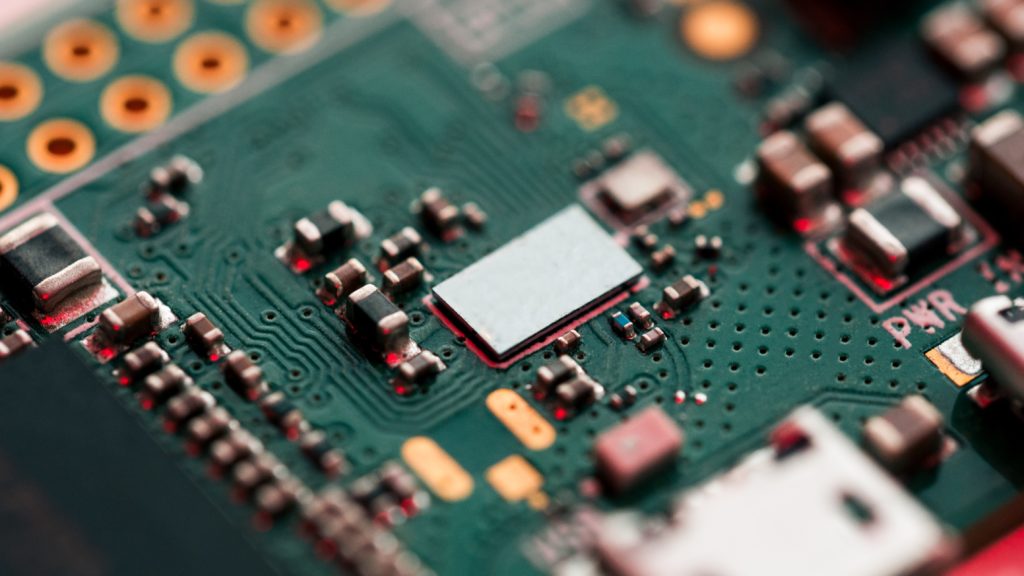

Semiconductor manufacturing relies heavily on the semiconductor FAB and OSAT. Semiconductor FAB turns the design into fabricated wafers. On another side, OSATs convert fabricated wafers into finished goods. End customers to develop consumer and enterprise solutions using the finished goods.

Semiconductor FAB and OSAT are so critical that any bottleneck can directly impact the semiconductor supply chain. It was already evident from the semiconductor shortage, which did impact all the industries that rely on it.

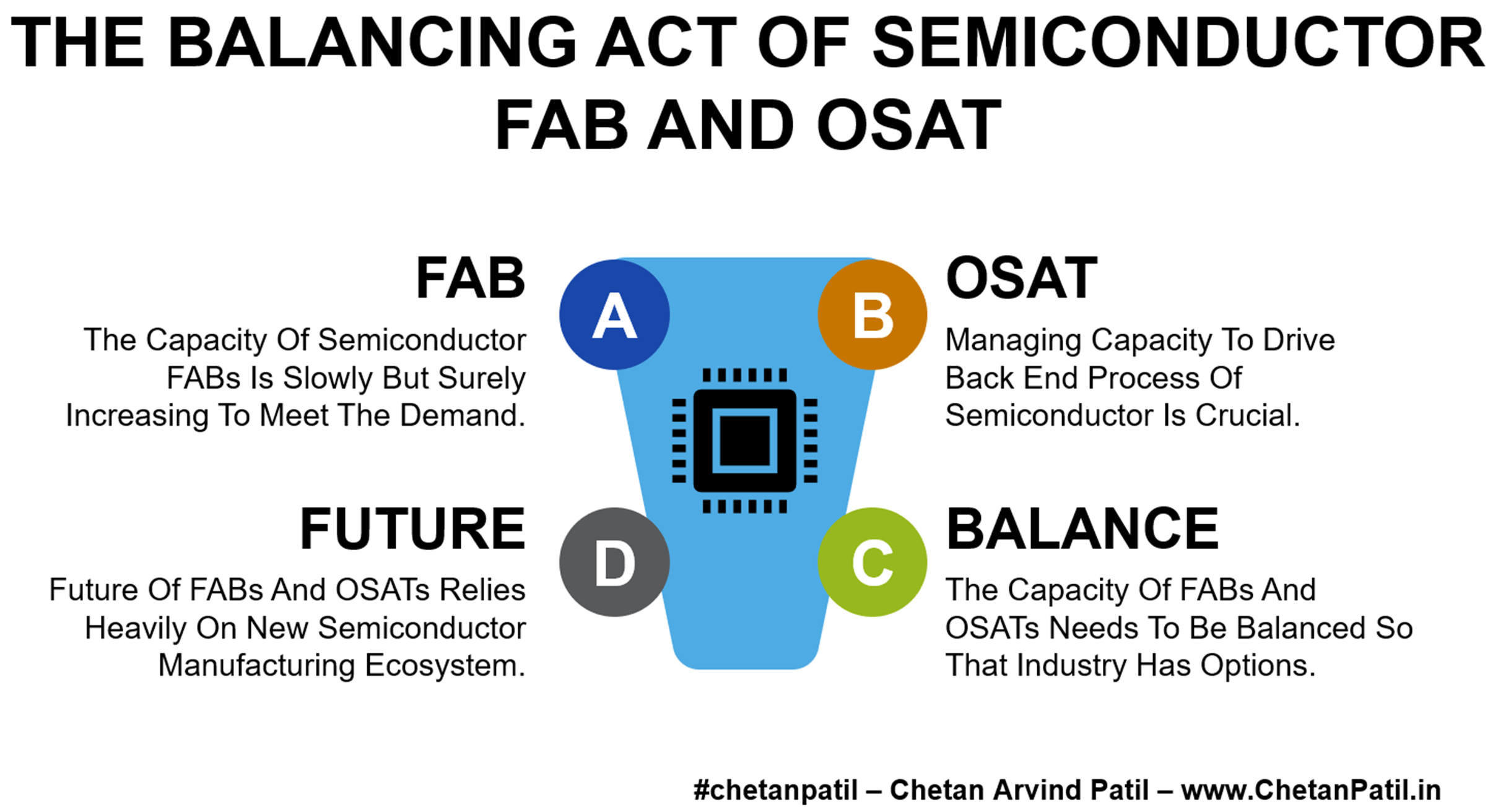

FAB: The Capacity Of Semiconductor FABs Is Slowly But Surely Increasing To Meet The Demand.

OSAT: Managing Capacity To Drive Back End Process Of Semiconductor Is Crucial.

Such significant dependency and impact are the primary reason FABs and OSATs need a balanced capacity that provides options to different customers and ensures the semiconductor industry is positively growing.

FABs and OSATs are also two different types of businesses. Managing these two requires a detailed overview of semiconductor technology node progress, assembly innovation, and testing developments. With the help of a technology roadmap, semiconductor manufacturing can also plan how to manage and expand capacity. As both FABs and OSATs need not grow in number together.

Worldwide, there is also a race to set up a semiconductor manufacturing ecosystem, and manufacturers have to take a call on whether to focus on FABs or OSATs.

In this process, new semiconductor manufacturing ecosystems get attracted toward the FABs. The primary reason seems to be the innovation and significance of the semiconductor industry. However, the business side also plays a vital role in developing the new semiconductor manufacturing ecosystem. In the long term, it might be better to focus on OSATs and build an ecosystem of raw materials, testing equipment, and the talent trained at handling the assembly process.

Balance: The Capacity Of FABs And OSATs Needs To Be Balanced So That Industry Has Options.

Future: Future Of FABs And OSATs Relies Heavily On New Semiconductor Manufacturing Ecosystem.

Then, using the platform created by the OSAT business, the new semiconductor manufacturing ecosystem can focus on building the FABs and thus slowly creating the end-to-end semiconductor manufacturing ecosystem. There are a few countries that have followed this process and have created a niche of their own.

As the focus on building better and larger semiconductor FABs and OSATs grows, the crucial point will be which capacity to focus on and plan. So that it not only benefits the location but also pushes the semiconductor industry forward.